ROBISCAN®

100% security with a minimum pseudo error rate: The Robiscan system reliably finds defects, bumps and dirt on surfaces and weld seams.

This flexible test system detects the smallest defects

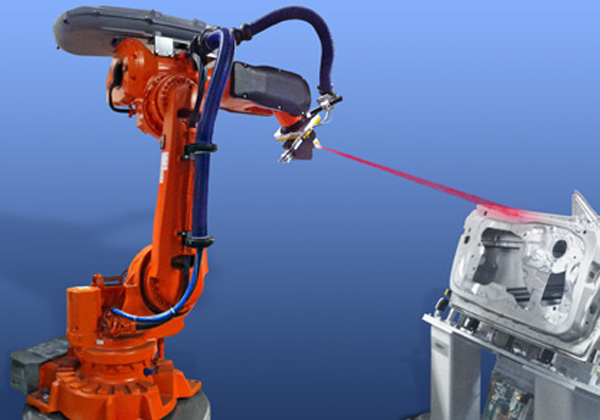

The Robiscan® platform inspects surfaces, welded and soldered seams much more reliably than the human eye. A high-quality appearance and the strength of the welds are guaranteed.

- Inspection of surfaces, shape or dimensions (as shown in applications below)

- 2D and 3D inspection heads in different versions

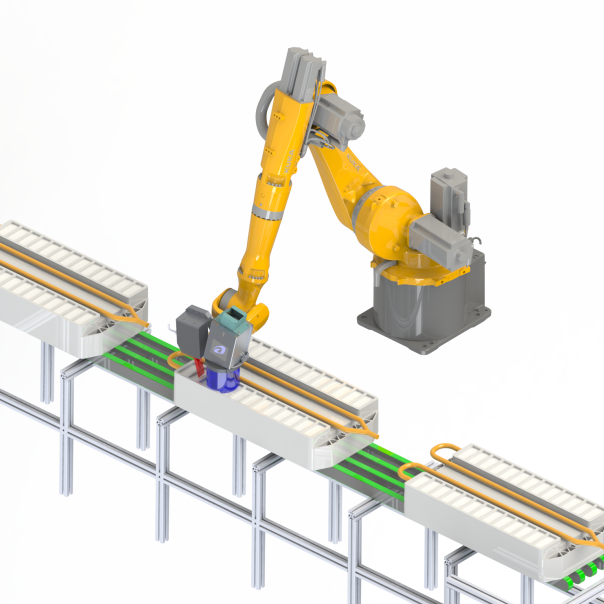

- Part or inspection head is usually guided by a robot or axis system

- Suitable evaluation systems for every performance class

- Extensive range of accessories, e.g. hardware extensions, software (tools, displays, ...)

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Integer maximus facilisis quam vel laoreet.

Key points

Avoid expensive and reputation-damaging recall campaigns and contractual penalties with an objective testing system.

No configuration required: AI works fully automatically

No adjustment is necessary when production parameters change

Reduction of incorrectly ejected parts (pseudo scrap)

Continuous process optimization

Applications

You want to make your production more efficient through automation?

Contact us to find individually tailored solutions for your operation. In the last 40 years we have solved many more tasks than we can list here.

Why streamline quality control?

Numerous premium OEMs use the Robiscan as a standard inspection system in order to reliably offer their customers the highest quality. In addition to the reliability, they also appreciate the special flexibility of Robiscan. Because the special script language enables it to be used for a wide variety of tasks.

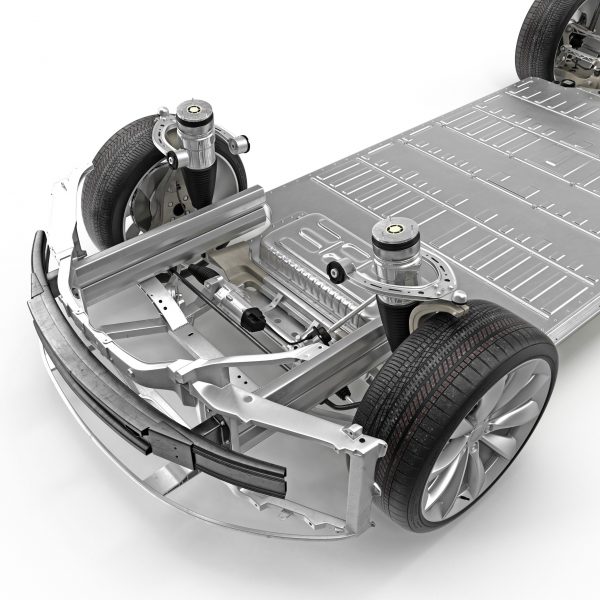

Another special feature of Robiscan: It can even check unpainted surfaces (e.g. sheet metal) so that defective parts can be identified at an early stage and further costs can be saved as a result.

Our solutions range from full inspection of entire car bodies with multiple robots to steel lamination at up to 20 parts/s.

This is how we recognize every mistake

For more than 40 years we have been developing our own detection methods, with which we push the limits of what is technically feasible.

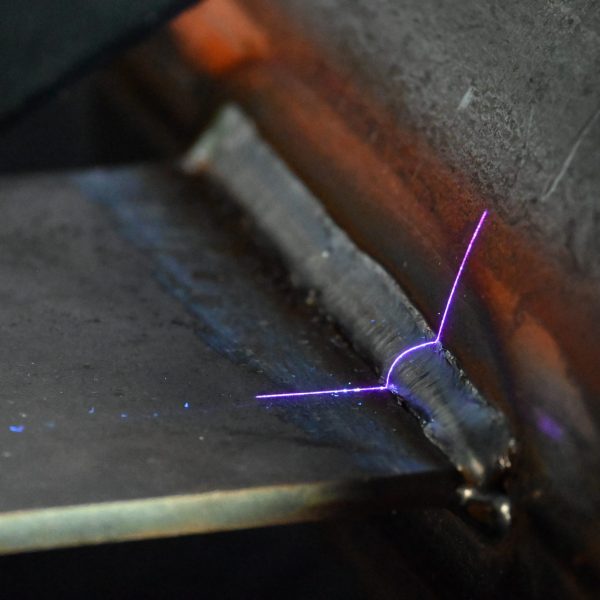

When testing the material, the probe is guided along the seam after the welding process. At the same time, images are created and evaluated in real time. In this way, even the smallest dents, scratches and notches are found. Minimal flaws such as pores or spatter (up to 50 µm) are reliably detected – with a minimal pseudo error rate (up to 0.004%).

We cover these seams:

- Welded and soldered seams

- E-mobility battery control

- Surface inspection

- Rivet control

- Steel industry

Solutions

Processing

Handling

Robot Vision

Mobile Robotics

- Automated Machine Loading and Unloading

- Palletizing and Depalletizing

- Testing