RobiCut

With the modular principle, we solve every problem of automated finishing. So you can deburr, grind, cut, mill or brush almost any material and any workpiece size.

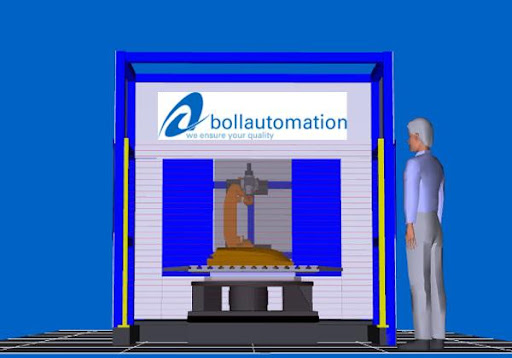

The Allrounder Robicut

In order to be able to process different materials and component sizes with maximum flexibility, we have developed a cell concept for robot-based finishing. The result is called Robicut.

Following the modular principle, Robicut is composed of flexible handling and feeding technology, innovative image processing systems and individually selected tools.

Applications

You want to make your production more efficient through automation?

Then contact us to find individually tailored solutions for your operation.. In the last 40 years we have solved many more tasks than we can list here.

Module 1: Process

First, a tool is selected: e.g. spindle, blade, knife, saw and others are available. The post-processing can optionally be tool- or workpiece-guided.

Module 2: Image Processing

You would like to integrate optical or sensory measuring or testing tasks? Then we install the appropriate image processing method upstream or downstream, which, in addition to post-processing, realize e.g. measuring or testing tasks.

Module 3: Handling Technology

Depending on the component size, the ideal robot for your finishing task can be selected from a wide range of robot models and manufacturers.

Module 4: Material Flow/ Feeding

Conveyor belts, rotary positioners or other workpiece carrier systems are available as feeding methods. By using a tool changing station, different tools can be used for machining.

Module 5: Chip removal

Choose the preferred variant of chip removal. For example, by conveyor technology, suction or in the drawer system.

Module 6: Safety concept

We offer closed and open cell concepts with different safety models.

Module 7: Programming

Path planning for your finishing or deburring task is done according to your requirements: Fully automated, partially automated, manual or even interactive.

Solutions

Processing

Handling

Robot Vision

Mobile Robotics

- Automated Machine Loading and Unloading

- Palletizing and Depalletizing

- Testing