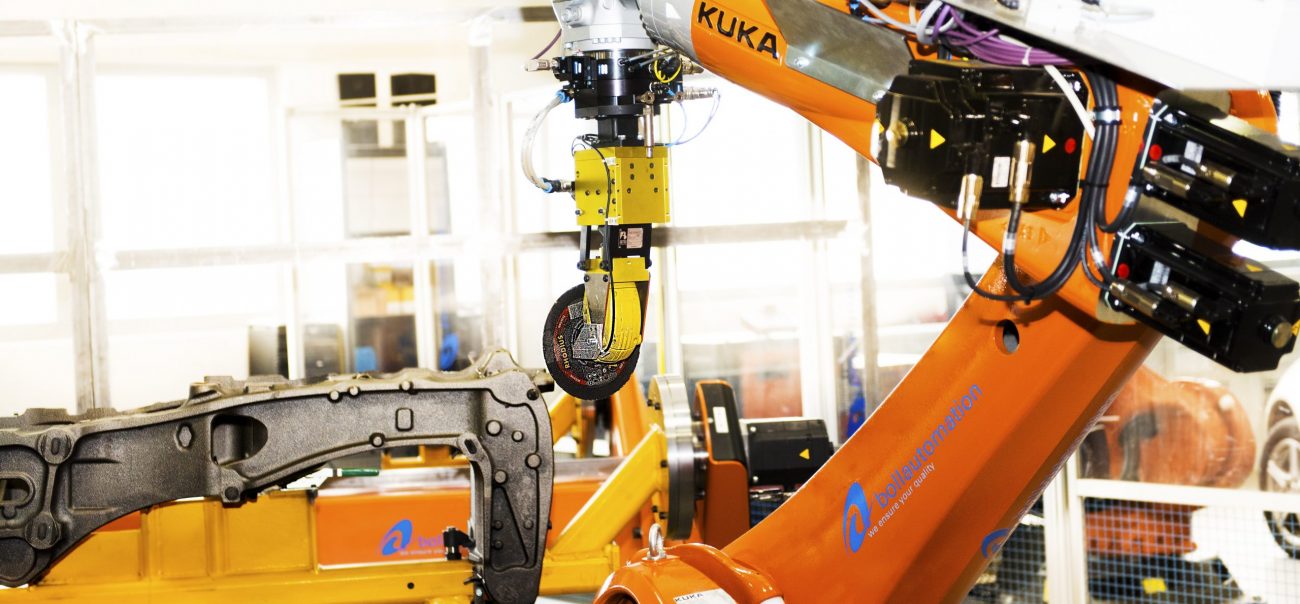

Cast Cleaning Cell

Robotic assisted fettling – Rely on the benefits of post-processing tasks through the use of robots, intelligent sensor technology and tooling technologies.

With the Cast Cleaning Cell, fettling becomes an entirely different experience. Because

- Employees are relieved of this heavy and dangerous activity

- the intensity of the post-processing is individually adjusted to the respective deviations

- the quality of the castings remains permanently constant and at the highest level

- automated fettling ensures shorter cycle times and thus higher yields

Study the improvement of efficiency and flexibility through the Cast Cleaning Cell in the production of Heidenreich and Harbeck GmbH .

Key points

With the fettling cell, the machining process is individually optimized on the respective workpiece. Accordingly, it can be used in every step of production.

High repeatability even with different ridge characteristics

Easier working conditions for your employees

Upstream Contour Detection

Deflectable and sensor-assisted molds

Applications

You want to make your production more efficient through automation?

Contact us to find individually tailored solutions for your operation. In the last 40 years we have solved many more tasks than we can list here.

Why process automation?

In addition to decreasing production costs and increasing quantities, robot-based machining solutions reduce the burden on those employees who previously had to perform these tasks manually.

Flying chips and the use of heavy tools, such as cutting and grinding wheels, pose an acute risk of injury to their employees. It is not for nothing that trade associations demand the use of automation technologies to provide employees with an ergonomic working environment and thereby protect them from monotonous and physically demanding activities.

Optimal division of labor between humans and robots ensures high safety

To further increase the safety aspect, the mold change takes place in a designated safety zone. The operator can carry out a mold change in this zone while the robot is simultaneously working on the casting.

Tool wear is automatically checked in the process within a few seconds. In this way, the wear material is utilized to the maximum and the operator of the system knows at all times how many operations are still possible with this tool. This allows him to react in time and safely replace the wheel.

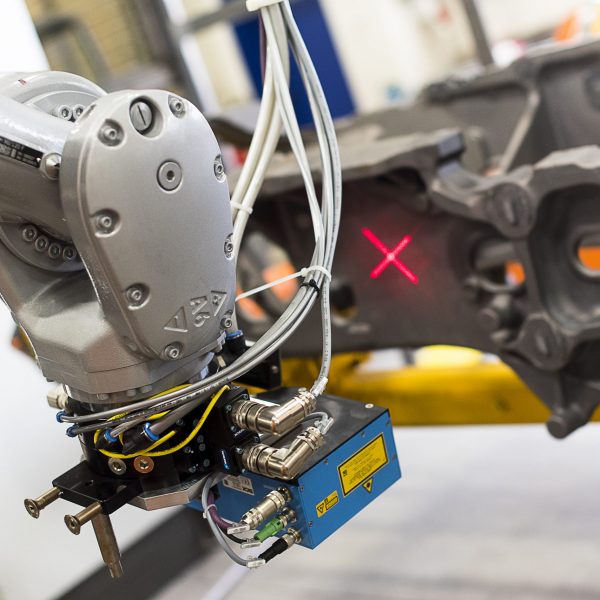

Example laser weld seam inspection

Robiscan is a high-end inspection system for tactile laser welding and soldering seams. It reliably detects even the smallest defects such as pores or splatters (to 50µm) while at the same time keeping the pseudo defect rate to a minimum (to 0.004%). Numerous large premium OEMs use Robiscan as standard in their production.

This high level of reliability is achieved through numerous in-house developments, such as the hardware-independent vibration compensation or the powerful evaluation procedures. Robiscan determines up to 40 geometric characteristics (e.g. depth, width, diameter, etc.) for each defect. As user, you can define the inspection rules, where required.

Solutions

Processing

Handling

Robot Vision

Mobile Robotics

- Automated Machine Loading and Unloading

- Palletizing and Depalletizing

- Testing